Industrial Sector

Did you know?

The industrial sector in California spends more than $15 billion annually to operate manufacturing systems and equipment such as motors and pumps, compressed air systems, steam and process heating and cooling. Find out how your facility can save money, energy and the environment by browsing the resources in this section.

Energy News

LED Lighting Grows into Agricultural and Horticultural Sectors

This Summer, Save Money and Help Prevent Blackouts

Lights Out for Earth Hour This Saturday

Cities Suffering from Localized CO2 Domes

e-Newswire Sign-Up Contest Continues, Congratulations to First 6 Winners

Energy-Saving Tips Cards

Download our hot weather energy-saving tips cards and reduce electricity costs as well as protect the environment.

Smart companies make energy efficiency an essential part of their business plan. By doing so, businesses lower their utility bills and help the state ensure a reliable energy supply.

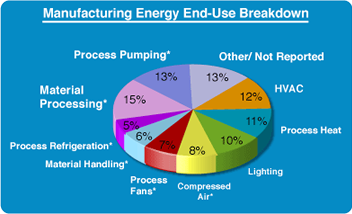

Manufacturing Energy End-Use Breakdown (2000)

* Motor-driven equipment. California Energy Commission, "California Energy Demand 2003-2013 Forecast," February 11, 2003, #100-03-002SD and Xenergy analysis.

It Pays to be Energy Efficient

During 2001 and 2002, nearly one-third of the state's businesses cut overall energy use at least 20%, saving California companies millions of dollars. For example, Lockheed Martin Missiles & Space Operations saved $4.8 million in annual energy costs. Other innovative industrial manufacturers recognized by Flex Your Power include E & J Gallo Winery, Allergan, Grundfos Pumps Manufacturing and the Port of Oakland.

Over the next decade, California could realistically and cost-effectively reduce peak – the hours when electricity use is highest – electricity needs by 5,900 Megawatts (MW), saving businesses and residents an estimated $12 billion.

Invest in Energy Efficiency Now

There are many opportunities to save energy and money – and improve operations – in industrial facilities. Energy efficiency upgrades can reduce energy by an estimated 30%. Improvements to facility steam systems can save 20% on energy bills. New technologies for motor systems can reduce energy by as much as 18%. Similar savings are available for improvements of both compressed air and process heating systems.

Key strategies for investing in energy efficiency include:

- Increase the efficiency of technology and equipment.

- Improve the design and efficiency of a plant's overall system.

- Introduce energy management and controls.

- Improve maintenance system.

This website contains many resources to help you upgrade your facility with energy-efficient equipment and building retrofits. If you are building a new facility, we can help you understand the benefits of building a facility that goes beyond Title 24 and other codes and standards.

Take advantage of Flex Your Power's Best Practices Guides and Tips. We can also help you find Rebates, Incentives & Services available to you through utilities and private and public sector companies.